Polishing Custom Anodized Aluminum CNC Machined Aluminum Parts

CNC Machining Shop

We operate almost every kind of CNC mill and turning center, and

pride ourselves on being able to machine whatever you need, from

simple, ‘as-machined’ work holdings to complex, organic geometries

with tight tolerances. On request, we can also produce parts with

EDM and grinders.

EDM

* The accuracy of wire cutting is comparable to that of a grinder

(0.005 mm unit)

* In addition to straight cutting, it can also cut into arcs and

process complex shapes, such as a combination of straight and arcs.

* As long as it is a conductive material, it can be machined from

sheet to cemented carbide regardless of the thickness, size and

hardness of the material.

EDM Electrodes

There is no direct contact between the tool electrode and the

workpiece, but there is a spark discharge gap. This gap is

generally between 0.05~0.3mm, and sometimes it may reach 0.5mm or

even larger. The gap is filled with working fluid, and the high

pressure Pulse discharge, discharge corrosion on the workpiece.

High Quality CNC OEM Machining Supplier |

| CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire

Cutting, Stamping, Electric Discharge Machining (EDM), Injection

Molding |

| Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

Titanium: GradeF1-F5 |

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK

etc. |

| Anodize, Bead blasted, Silk Screen, PVD Plating,

Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder

Coated, Passivation, Electrophoresis, Electro Polishing, Knurl,

Laser/Etch/Engrave etc. |

| +/-0.002~+/-0.005mm |

| Min Ra0.1~3.2 |

| Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF, or Samples |

| 1-2 weeks for samples, 3-4 weeks for mass production |

| ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV |

| Trade Assurance, TT/ PayPal/ WestUnion |

|

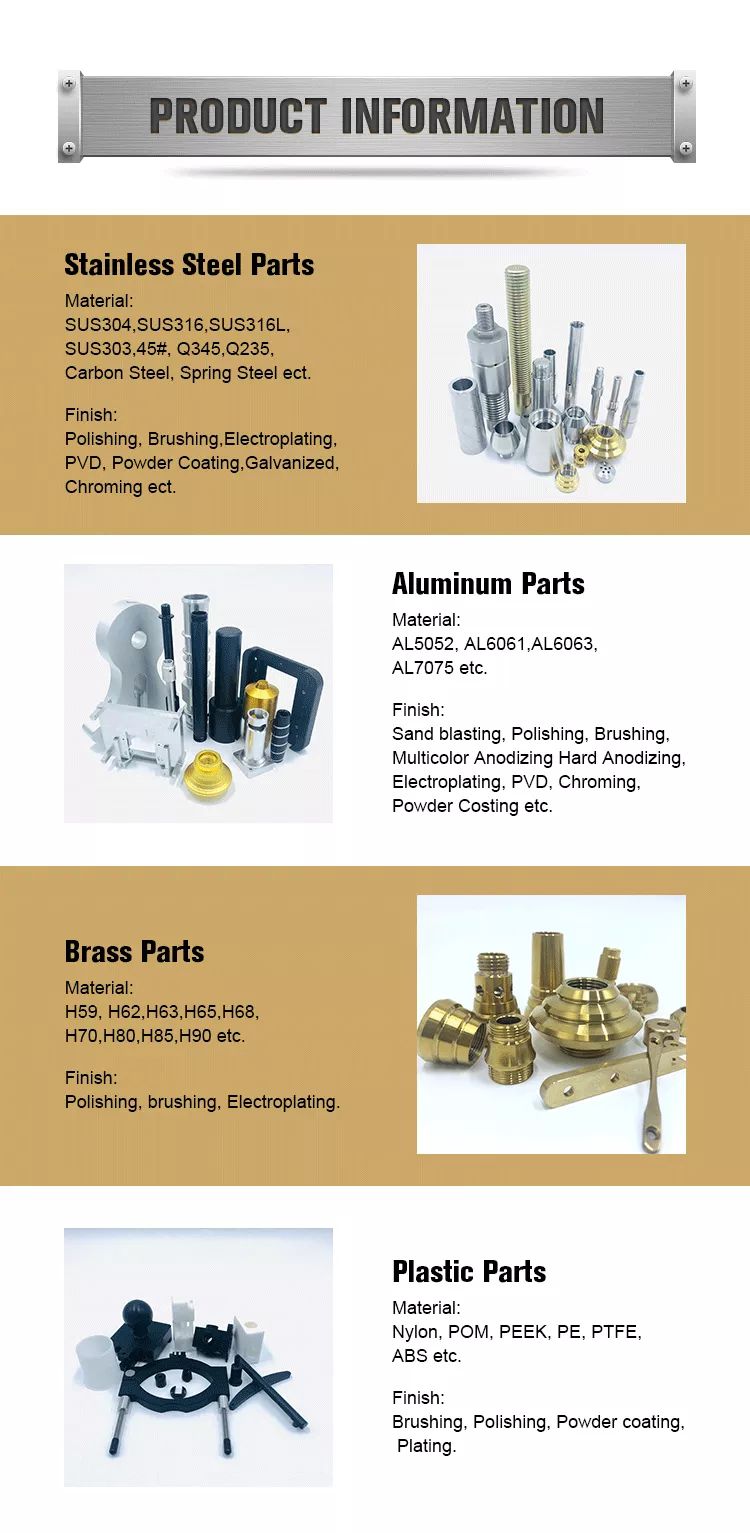

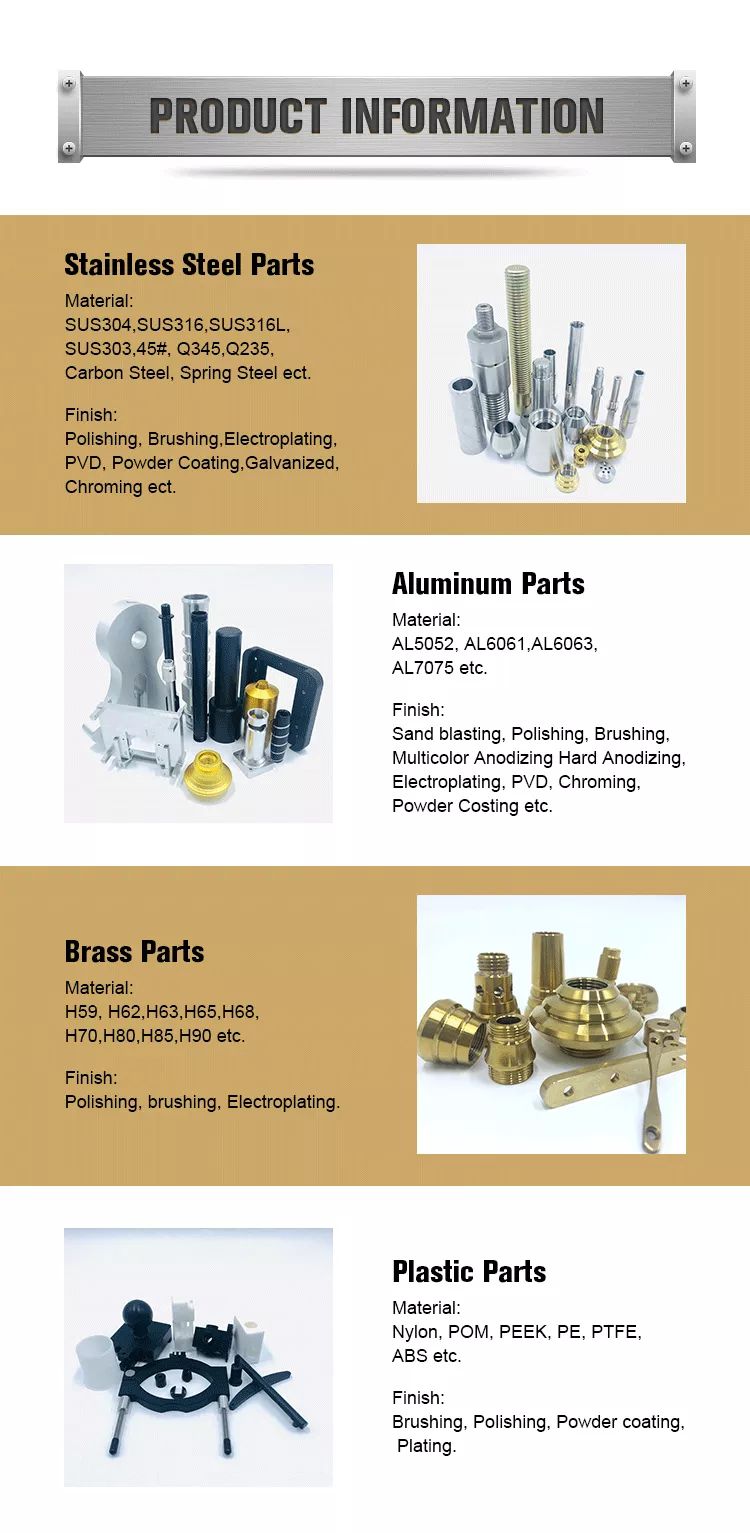

Aluminum | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. |

Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416, etc. |

Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. |

Brass | C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000,

C22000, etc. |

Copper | C11000, C12000, C12200, C10100, etc. |

Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

Plastic | POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc |

|

Stainless Steel | Brushed and Polishing, Passivating, Sandblasting, Laser engraving,

Gold Plating Etc. |

Steel | Zinc plating, Oxide black, Nickel plating, Chrome plating,

Carburized, Powder Coated |

Aluminum Parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,

Brushing, Polishing, Powder Coated, Nickel Plated Etc. |

Plastic | Plating gold (ABS), Painting, Brushing (Acrylic), laser engraving |

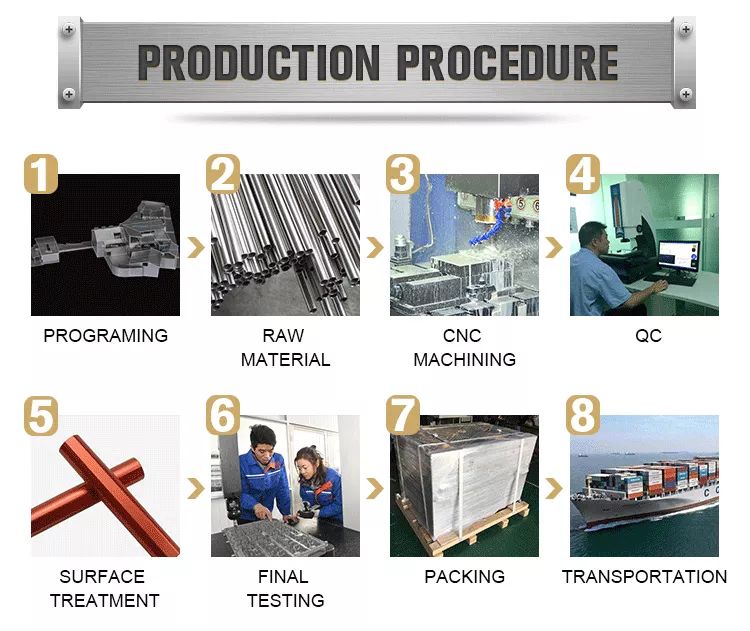

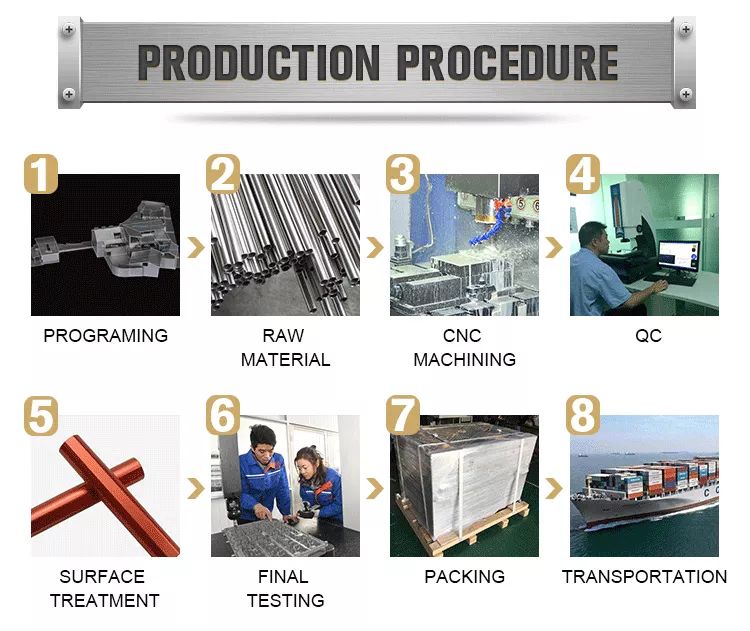

1) Checking the raw material after they reach our factory-------

Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass

production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality

control(FQC)

5) Checking the goods after they are finished-----Outgoing quality

control(OQC)

We can supply products with follow test reports : |

1) Chemical composition report |

2) Tensile strength report |

3) Brinell hardness report,Rockwell hardness. |

4) Metallographic structure report |

5) Key dimension checking record report |

6) Full dimension report |

7) Third-party test report |

About us:

Suzhou Yongxu Precision Hardware Products Factory is a professional

manufacturer of precision hardware accessories. We have many years

of technical precipitation in the manufacture of metal precision

parts. Our main products include: non-standard micro components,

stainless steel components, medical equipment accessories, lighting

accessories, fasteners, connectors, instrumentation accessories,

shaft sleeves, Fiber optic connectors, lc tail handle, sc tail

handle, precision mechanical parts, optical fiber communication

accessories, screws and nuts, electronic product accessories,

copper, aluminum rivets and other high-standard, high-quality, and

clean products are available for customers to choose. Existing

equipment Tsugami six-axis core walking machine, turning and

milling compound machining center, turret machine, slow wire

walking and so on. The testing equipment includes two-dimensional,

altimeter, high-power microscope, micrometer, etc., advanced

production management system, practical and innovative scientific

and technological talents. In addition, we can also manufacture

products that satisfy customers according to different requirements

of customers.

FAQ:

Q. What raw material do you use?

A: Different series of Aluminum alloy, Stainless Steel, Brass,

Plastic, Steel, etc.

Q. What finishes can you provide?

A: powder coating, polishing, zinc/nickel /chrome plating,

painting, anodized, hot-dip galvanized, sandblasted etc.

Q. How do you ensure quality control?

A: We inspect every process based on your drawings or samples and

also check the products before packing.

Q. Is a small quantity available?

A: Yes, small quantity for trial order is available.